Designed

for proportional conversion of gauge pressure of liquids, gases, or vapors to standard DC output signal.

Used in central process monitoring and control systems at power, heat, water, oil and gas supply facilities; at housing and utilities facilities, in local automation systems for pump, compressor, etc. equipment, and in process monitoring systems.

Selection of a pressure transmitter

Pressure is as important physical value as, for instance, temperature. Nowadays this is the value that is considered critical in the course of many process procedures. – page 74 of the Catalog

In most cases, gauge pressure transmitters are intended for measuring continuous conversion of pressure into output unified signals of DC voltage or into a digital signal.

As other devices of modern automatics, regulators use transmitters responsible for regulation and control of many process procedures in heating, water treatment, air conditioning, ventilation systems, etc.

Which are the algorithms to be considered for selection of a transmitter?

Type of measured pressure is the main factor worth special attention when purchasing gauge pressure transmitters. At present, pressure transmitters can measure only the difference of two pressures affecting the measuring membrane: the measured and the reference values. Depending on the types of reference pressure, transmitters are divided into the following types:

Absolute pressure transmitters are responsible for measurement of values of absolute pressure in gaseous and liquid phases. Relative (gauge) pressure transmitters are used for measurement of the value of gauge pressure of gaseous and liquid phases.

Differential pressure (pressure drop, pressure difference) transmitters measure the difference in phase pressure. Used for measuring flowrate of gas, liquids, steam, etc.

There are transmitters of so-called vacuum gauge pressure, which are responsible for measurement of values of vacuum gauge pressure of gaseous and liquid phases. Hydrostatic pressure level transmitters are intended for conversion of indications of hydrostatic pressure of this or another controlled medium into DC signals. As to vacuum/gauge pressure transmitters, they are a perfect combination of vacuum gauge and gauge pressure transmitters.

In addition, when selecting gauge pressure transmitters, it is necessary to consider their environment as well as climatic version of pressure transmitters. Their output signals are very important: analog, output, radiometric. Measurement accuracy of pressure transmitters should not be overlooked. Some are also divided into several types depending on various metrological characteristics (accuracy classes).

General specifications

|

Upper range limit, MPa

|

0.25; 0.4; 0.6; 1.0; 1.6; 2.5; 4; 6; 10; 16; 25; 40

|

|

Output signal, mA

|

4–20

|

|

Allowable basic error limit, %

|

± 0.5; ± 1.0

|

|

Supply voltage, V

|

24+6-15

|

|

Load resistance, Ohm

|

0.1 to 500

|

|

Power consumption, V•А, as maximum

|

1.0

|

|

Climatic version:

|

УХЛ 3.1 – for operation at a temperature from minus 10oC to plus 80°С and air relative humidity 95% at 35°С and lower temperatures with no moisture condensation.

Temperature of measured medium is from minus 20oС to plus 150oС (if temperature exceeds plus 80oС, transducers shall be connected using a cooling radiator or pulse tube)

|

|

IP rating

|

IP65

|

|

Calibration interval

|

2 years

|

|

Guarantee service life

|

1.5 years

|

|

Weight, kg, maximum

|

0.2

|

Ordering

When ordering, it is required to specify the following:

- Designation (composed as per diagram specified below).

- ТУ designation (ТУ4212-133-00227471-2008).

Order examples

Gauge pressure transmitter ПД-Р with an upper range limit of 0.6 MPa, with an allowable basic error limit of ±0.5%, with М20х1.5 coupling thread:

“Gauge pressure transmitters ПД-Р–0,6МПа–0,5–М20 ТУ 4212-133-00227471-2008”.

Gauge pressure transmitter ПД-Р with an upper range limit of 2.5 MPa, with an allowable basic error limit of ±1.0%, with G1/2 coupling thread: “Gauge pressure transmitters ПД-Р–2,5МПа–1,0–G1/2 ТУ 4212-133-00227471-2008”.– page 75 of the Catalog

Leading Supplier is JSC Research and Production Company RASKO, Moscow

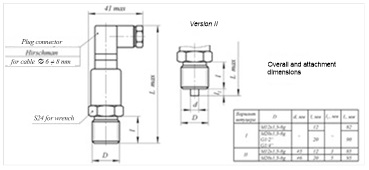

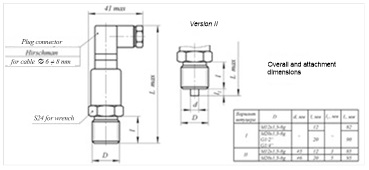

Overall and attachment dimensions